Light duty Castor, Top-plate, Swivel, Total Brake, 50 mm PU wheels, Color Red

Bracket: L1 series

• Pressed Steel and Zinc Surface treatment

• Double ball bearing in the swivel head

• Swivel head sealed

• With Total Brake

• Minimum swivel head play and smooth rolling characteristic and increased service life due to the special dynamic riveting.

Wheel:

• Wheel tread: Red PU wheel, non-marking, non-staining

• Wheel rim: injection molding, Double ball bearing.

Other characteristics:

• Environmental protection

• wear resistance

• anti-slip

Technical data:

| Wheel Ø (D) | 50mm | |

| Wheel Width | 28mm | |

| Load Capacity | 70mm | |

| Total Height (H) | 76mm | |

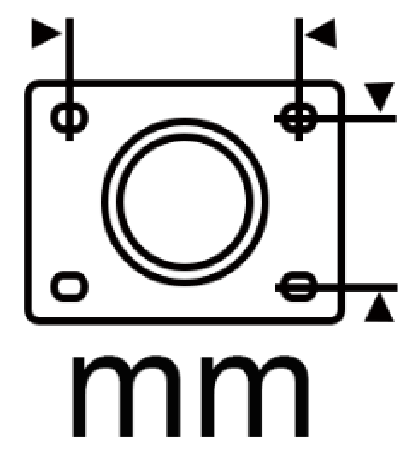

| Plate Size | 72*54mm | |

| Bolt Hole Spacing | 53*35mm | |

| Bolt Hole size Ø | 11.6*8.7mm | |

| Offset (F) | 33mm | |

| Bearing type | double ball bearing | |

| Non-marking | × | |

| Non-staining | × |

Product parameters

|

|

|

|

|

|

|

|

Wheel Diameter |

Load |

Overall |

Top-plate size |

Bolt Hole Diameter |

Bolt Hole spacing |

Product Number |

|

50*28 |

70 |

76 |

72*54 |

11.6*8.7 |

53*35 |

L1-050S4-202 |

Company Introduction

Zhongshan Rizda Castor Manufacturing Co., Ltd. Located in Zhongshan City,Guangdong Province,one of the central cities of the Pearl River Delta,covering an area of more than 10000 square maters,It is a professional manufacture of wheels and Castors to provide customers with a wide range of sizes,types and styles of products for a variety of applications.The predecessor of the company was BiaoShun Hardware Factory,founded in 2008 which have had 15 years of professional production and manufacturing experience.

Features

1. Its thermal deformation temperature is between 80 and 100 °C, indicating good heat resistance.

2. Good resistance to chemicals and toughness.

3. environmentally friendly, recyclable, odorless, and non-toxic material;

The ability to withstand corrosion, acid, alkali, and other substances. It is not significantly affected by common organic capacitors like acid and alkali;

5. Tough and rigid, it has a high bending fatigue life and is resistant to stress cracking and fatigue. Its performance is unaffected by a humid environment.

6. The benefits of bearings include high sensitivity and accuracy, low friction, relative stability, and non-changeability with bearing speed.

FAQ About Light Duty Castors

Light duty castors are versatile and commonly used components in various industries and applications. These small but essential wheels are ideal for lighter loads and can be found in office furniture, small carts, medical equipment, and more. Below are some frequently asked questions (FAQs) about light duty castors.

1. What is a light duty castor?

A light duty castor is a type of wheel and mounting assembly designed to carry lighter loads, typically under 100 kg (220 lbs). These castors are used in applications such as office chairs, trolleys, and small equipment where mobility is required without heavy load-bearing demands. They are usually smaller in size compared to heavy-duty castors.

2. What materials are light duty castors made of?

Light duty castors are made from various materials to suit different surfaces and operational needs. Common materials include:

- Polyurethane: Offers smooth, quiet movement and is gentle on floors.

- Nylon: Known for durability, abrasion resistance, and cost-effectiveness.

- Rubber: Provides cushioning and is ideal for shock absorption.

- Steel: Often used for the frame or mounting bracket due to its strength. The choice of material depends on the type of floor, load weight, and desired level of noise reduction.

3. What types of light duty castors are available?

Light duty castors come in different configurations, including:

- Swivel Castors: These castors can rotate 360 degrees, making them ideal for situations where easy maneuverability is important, like office chairs or carts.

- Fixed Castors: These castors are rigid and can only roll in a straight line, providing stability in situations where directional control isn’t a priority.

- Braked Castors: These castors feature a brake mechanism that locks the wheel in place, preventing movement when required.

4. What is the load capacity of light duty castors?

Light duty castors are typically designed to carry loads ranging from 10 kg to 100 kg (22 lbs to 220 lbs) per castor. The total load capacity will depend on the number of castors used. For example, a piece of equipment with four castors could handle a load of up to 400 kg (880 lbs) when using light-duty castors, depending on the load distribution.

5. How do I choose the right light duty castor?

When selecting a light duty castor, consider the following factors:

- Load Capacity: Ensure the castor can handle the weight of the object it will support.

- Wheel Material: Choose a wheel material based on the floor type (e.g., rubber for soft floors, polyurethane for hard floors).

- Wheel Diameter: Larger wheels provide smoother movement over rough surfaces.

- Mounting Type: The castor should match the mounting hole pattern of the equipment you are using.

- Braking Mechanism: If you need to stop the movement of the castor, opt for one with a brake.

6. Can light duty castors be used on outdoor surfaces?

Light duty castors are generally designed for indoor use. However, some models made from materials like rubber or polyurethane can tolerate outdoor conditions, though their lifespan might be shorter compared to heavy-duty castors designed specifically for outdoor use. Ensure that the castor material is suitable for exposure to weather and environmental conditions.

7. How do I maintain light duty castors?

To maintain light duty castors:

- Regular Cleaning: Keep the wheels free from dirt, debris, and dust, which can cause friction and wear.

- Lubrication: Periodically lubricate the bearings to ensure smooth rotation.

- Inspect for Wear and Tear: Check for any damage or signs of wear, such as flat spots or cracks in the wheel. Replace castors if necessary to maintain mobility.

- Check Brakes: If your castors have brakes, make sure they are functioning properly to prevent unwanted movement.

8. What surfaces can light duty castors be used on?

Light duty castors are suitable for use on most indoor surfaces, including:

- Carpet (depending on the wheel type)

- Hardwood floors

- Tiles

- Concrete They are not typically recommended for rough or uneven outdoor surfaces, as they may wear down more quickly. For outdoor use or heavy-duty surfaces, consider opting for more robust castors.

9. Can light duty castors be used on furniture?

Yes, light duty castors are commonly used on furniture such as office chairs, desks, and carts. They make it easy to move heavy or bulky furniture without causing damage to floors. In office environments, castors help improve mobility and allow furniture to be rearranged easily.

10. How do I install light duty castors?

Installation of light duty castors is typically straightforward. Most castors come with either a threaded stem, plate mount, or press-fit design:

- Threaded Stem: Simply screw the stem into the designated hole in the equipment or furniture.

- Plate Mount: Bolt the castor onto the mounting plate, ensuring it is securely fastened.

- Press-Fit: Push the castor into the mount or housing until it locks into place.