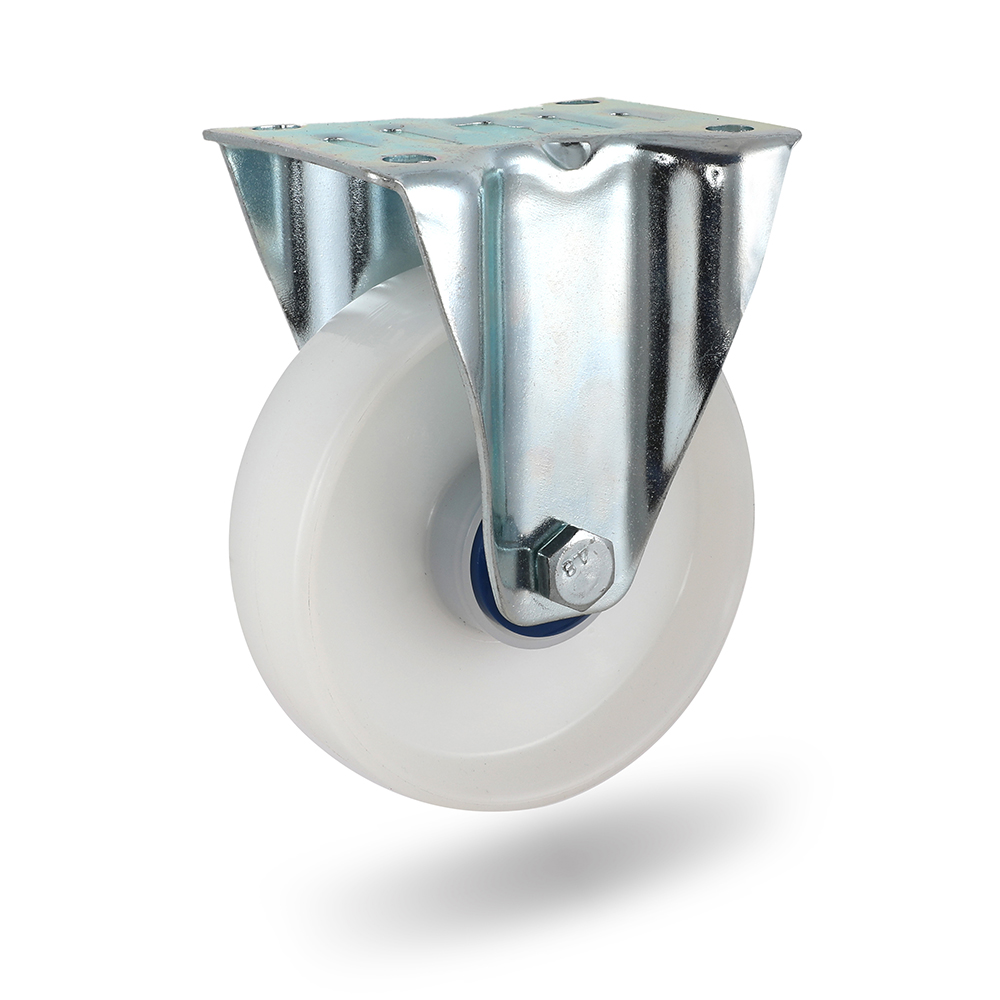

125mm (Polypropylene) PP Wheels, Fixed, Medium Duty Castors, European stamping industrial bracket, Zinc ( galvanized) surface

Bracket: R series

• Pressed Steel and Zinc Surface treatment

• Fixed Bracket

• Fixed castor support can be fixed on the ground or other plane, avoiding the equipment the use of shaking and shaking, with good stability and safety.

Wheel:

• Wheel tread: White PP (Polypropylene ) wheel, non-marking, non-staining

• Wheel rim: injection molding, Central precision ball bearing.

Other characteristics:

• Environmental protection

• wear resistance

• Shock Resistance

| Wheel Ø (D) | 125mm | |

| Wheel Width | 36mm | |

| Load Capacity | 150mm | |

| Total Height (H) | 155mm | |

| Plate Size | 105*80mm | |

| Bolt Hole Spacing | 80*60mm | |

| Bolt Hole size Ø | 11*9mm | |

| Offset (F) | 38mm | |

| Bearing type | Single ball bearing | |

| Non-marking | × | |

| Non-staining | × |

Product parameters

|

|

|

|

|

|

|

|

|

|

|

|

Wheel Diameter |

Load |

Axle |

Bracket |

Load |

Top-plate Outer Size |

Bolt Hole Spacing |

Bolt Hole Diameter |

Opening |

Product Nunber |

|

80*36 |

120 |

/ |

2.5 |

108 |

105*80 |

80*60 |

11*9 |

42 |

R1-080R-111 |

|

100*36 |

150 |

/ |

2.5 |

128 |

105*80 |

80*60 |

11*9 |

42 |

R1-100R-111 |

|

125*36 |

160 |

/ |

2.5 |

155 |

105*80 |

80*60 |

11*9 |

52 |

R1-125R-111 |

|

125*40 |

180 |

/ |

2.5 |

155 |

105*80 |

80*60 |

11*9 |

52 |

R1-125R-1112 |

Features

1. Good heat resistance: its thermal deformation temperature is 80-100 ℃.

2. Good toughness and chemical resistance.

3. Non-toxic and odorless, environment-friendly material, recyclable;

4. Corrosion resistance, acid resistance, alkali resistance and other characteristics. Common organic capacitors such as acid and alkali have little impact on it.

5. Rigid and tough, with the characteristics of fatigue resistance and stress cracking resistance, its performance is not affected by humidity environment; It has a high bending fatigue life.

6. Single ball bearing has low noise and long service life. The advantage is that the noise will not increase after long-term use, and no lubricant is required.

Customizing Procedure

1. Clients give drawings, which R&D Management examines to determine whether we have items that are similar.

2. Clients supply samples, we analyze the structure technically and create designs.

3. Take mold production costs and estimates into consideration.